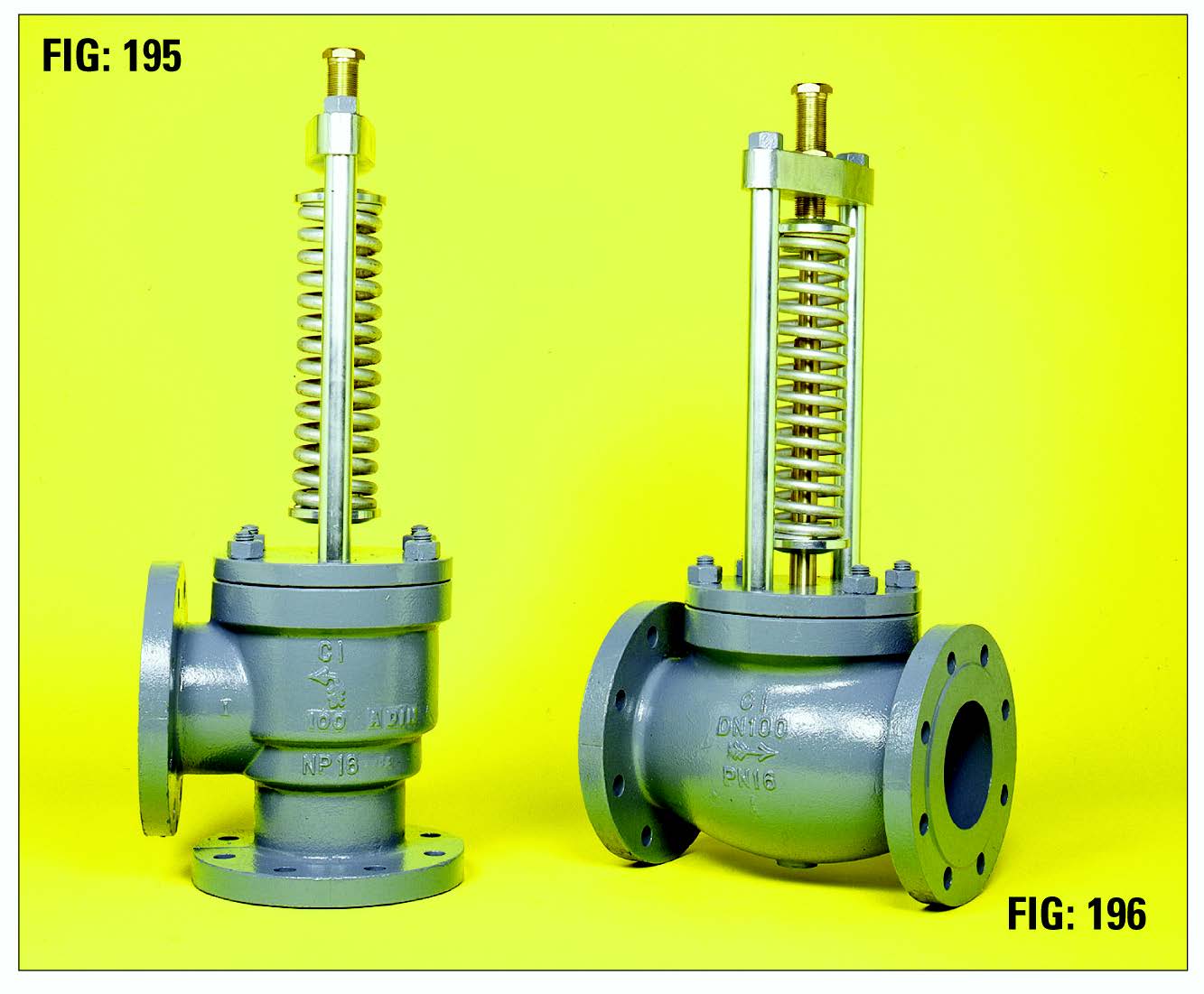

Cast Iron Relief Check for Liquids (external spring)

PRESSURE / TEMPERATURE RATING: (detailed on Valve ID Plate)

Min/Max spring set Pressures

Min Set Pressure 5psi (0.35 Bar)

Max Set Pressure 116psi (8.0 Bar)

MAX TEMPERATURE 40°C

FOR WATER INDUSTRY USE ONLY WITHIN THE EUROPEAN COMMUNITY

FLANGED:

- BS EN 1092-2 – PN6, PN10, PN16

- BS 10 TABLES – D, E, F

- ANSI B 16.1 – CLASS 125

CONSTRUCTION:

- This traditional design is suitable for systems with open discharge to atmosphere.

- The external spring is not in contact with the discharge liquid.

- The valve is intended to relieve excess liquid, and must not be used as a safety valve to prevent system failure as referenced in the Pressure Systems Safety Regulations SI 2000 No 128

- Flanges will be drilled unless otherwise specified on order

MATERIALS:

- Body/Cover – Cast Iron to BS EN 1561 EN GJL 250

- Disc – Stainless Steel Casting ASME SA 487 CA6NM class A

- Seat Ring – Stainless Steel Casting to BS EN 10283 1.4408

- Spring – Spring Alloy Steel Design in accordance with BS 1726 Chrome Vanadium Alloy Coated

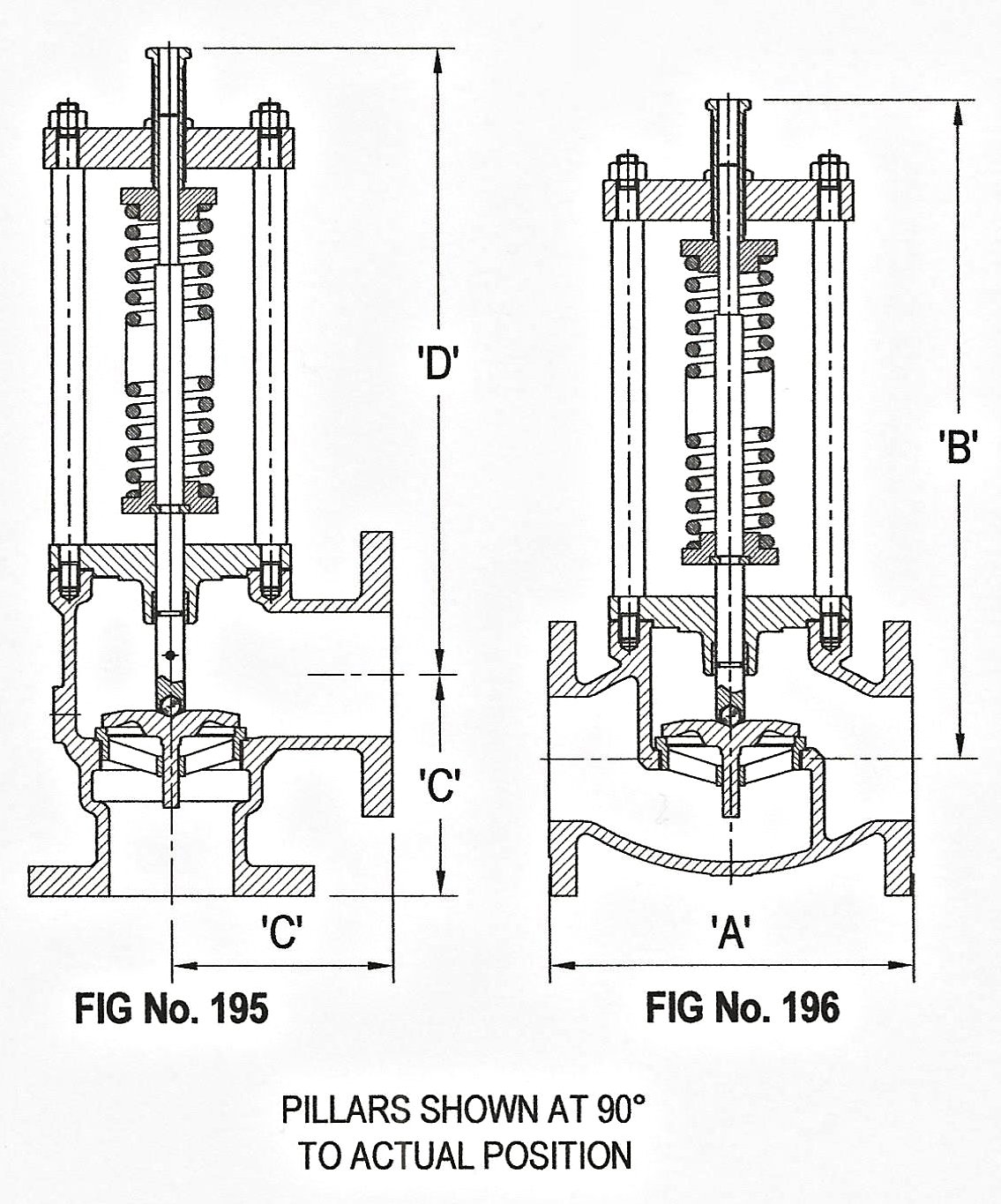

| Nominal Size (Fig.195) | 50 | 65 | 80 | 100 |

| A | 125 | 145 | 155 | 178 |

| B | 316 | 372 | 410 | 527 |

| Nominal Size (Fig.196) | 50 | 65 | 80 | 100 |

| A | 203 | 216 | 241 | 292 |

| B | 324 | 368 | 421 | 544 |

| STANDARD SPRING RANGE |

| Nominal Sizes 50mm to 100mm |

| Spring No. | PSI | Bar |

| 1 | 5-13 | 0.35-0.9 |

| 2 | 10-25 | 0.7-1.7 |

| 3 | 20-50 | 1.4-3.5 |

| 4 | 40-100 | 2.7-6.9 |

| 5 | 90-230 | 6.2-8.0 |

OPTIONAL EXTRAS:

- Easing Lever and cover Locking Unit

TYPE OF APPLICATION:

- Thermal & pressure relief

LINE MEDIA:

- Effluent

- Sewage Sludge