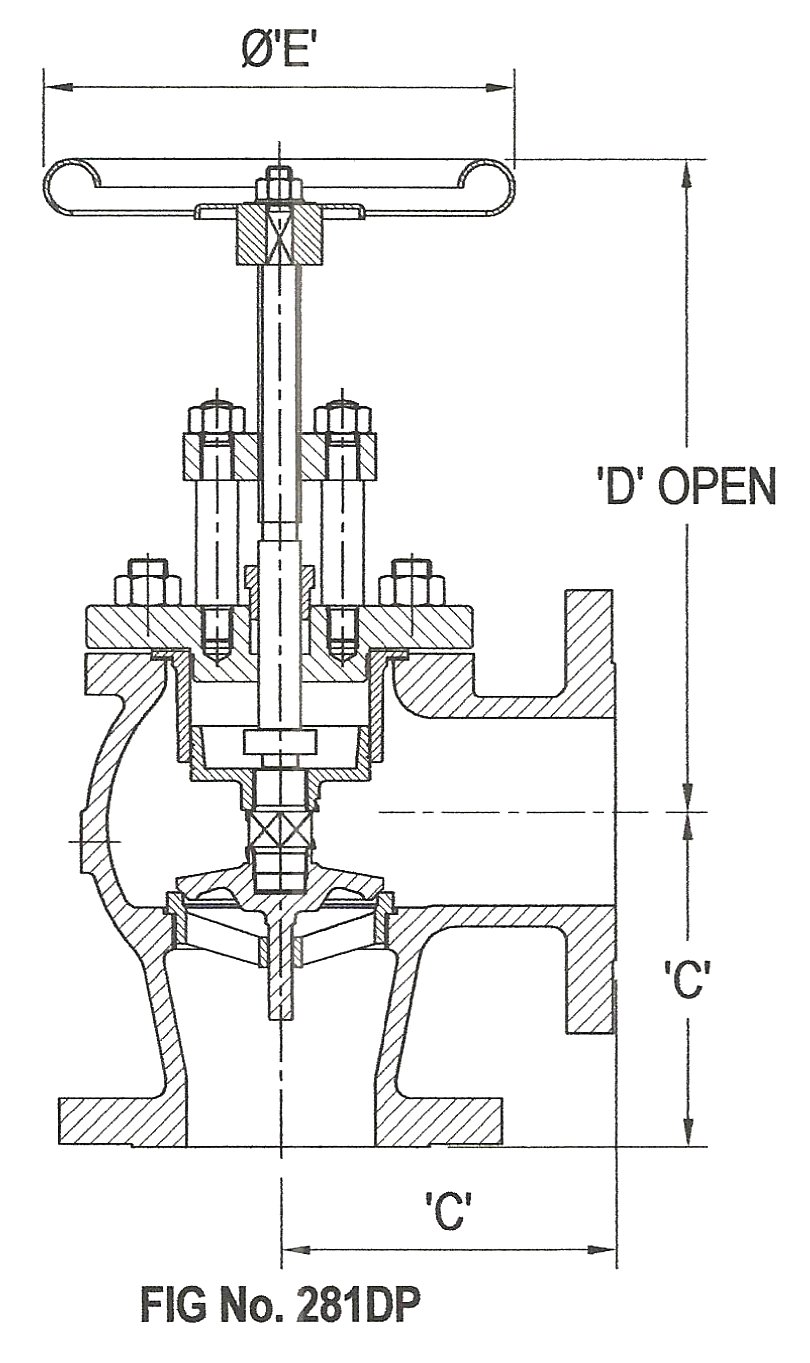

Cast Steel Angle Boiler Crown

PRESSURE/ TEMPERATURE RATING:

In accordance with BSI, BS EN 13709 (formerly BS5160*) and ANSI Specifications. For the Line Flange Connection required, refer to the Pressure Temperature Rating Chart in the Technical Data Section of our website.

FLANGED:

- BS EN 1092-1 – PN10, PN25, PN16 PN40

- BS 10 Tables – E,F,H,

- ANSI B 16.5 – Class 150

CONSTRUCTION:

- Bolted Cover, outside screw SDNR Valve with rising spindle.

- These Valves should be installed with the Valve Head Vertical.

- Supplied with internal dashpot to minimise noise & wear caused by chatter

- Flanges will be drilled unless otherwise specified on order

MATERIALS:

- Body – Carbon Steel to BS EN 10213 gr. GP240GH (WCB) 0.23%C max

- Cover – Carbon Steel BS EN 10028 161 – 430

- Disc – Stainless Steel Casting to ASME SA 487 CA6NM Class A

- Seat – Stainless Steel Casting to BS EN 10283 1.4408 (formerly BS 3100 316 C16)

- Stem – Stainless Steel to BS EN 10088-3 1.4006 (formerly BS 970 410 S21)

- Dashpot/Cylinder – Gunmetal to BS EN 1982 CC491K

- Gland Packing – Exfoliated Graphite

| Nominal Size | 80 | 100 | 125 | 150 | 200 | |

| C | PN 10 16 25 40 | 152 | 178 | 203 | 229 | 260 |

| BST E, F, H, ANSI 150 | 152 | 178 | 203 | 229 | 260 | |

| D | 333 | 372 | 457 | 577 | 665 | |

| E | 200 | 250 | 315 | 400 | 530 | |

| Weight Kg. | 36 | 54 | 85 | 120 | 207 | |

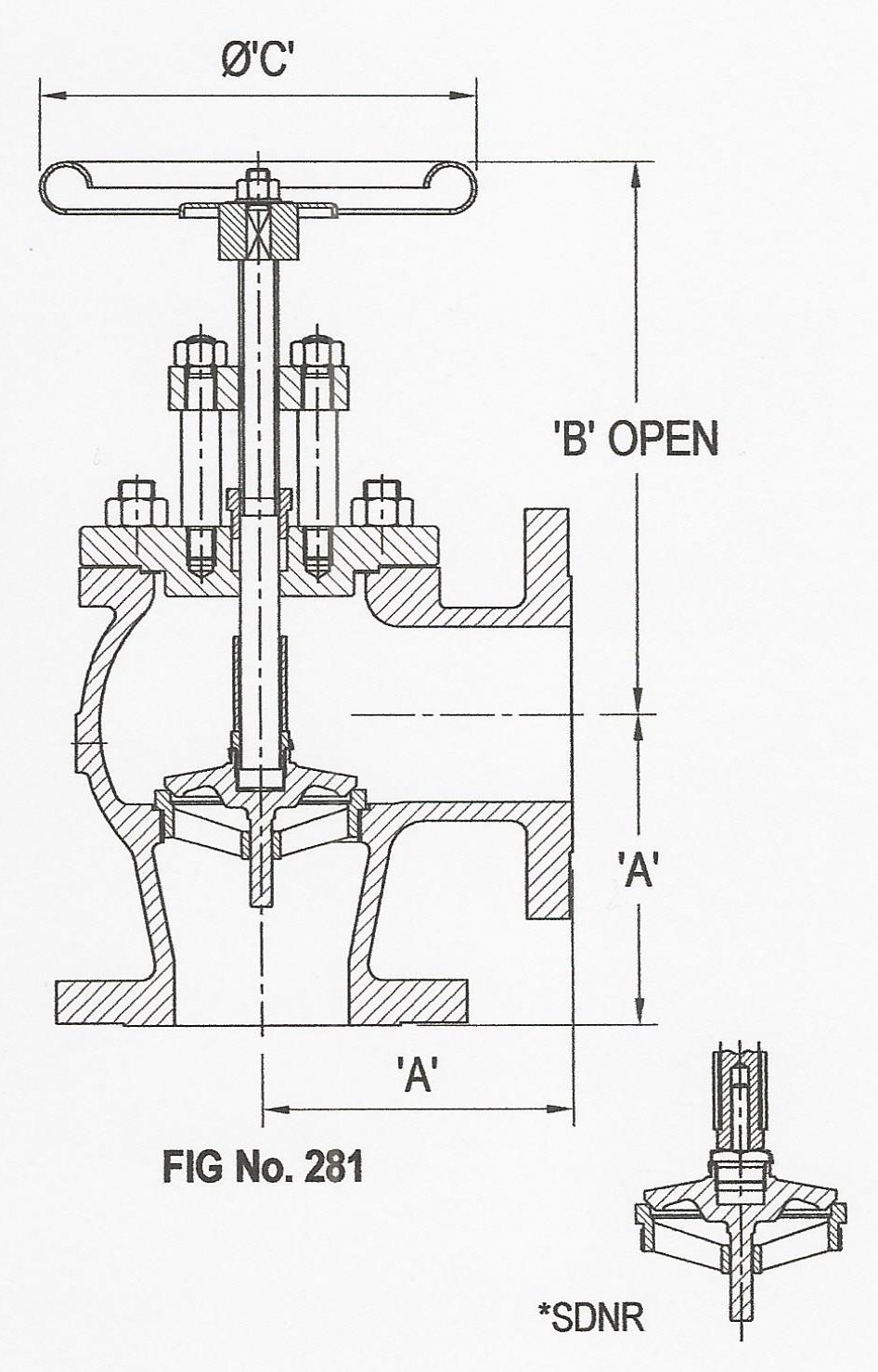

Gunmetal Angle Stop

PRESSURE/ TEMPERATURE RATING:

In accordance with BSI and ANSI Specifications. For the Line Flange Connection required, refer to the Pressure Temperature Rating Chart in the Technical Data Section of our website.

FLANGED:

- BS EN 1092-3 – PN6, PN10, PN16, PN25

- BS 10 Tables – D, E, F, H

- ANSI B 16.24 – Class 150

CONSTRUCTION:

MATERIALS:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

OPTIONAL EXTRAS:

- Locking Device

TYPE OF APPLICATION:

- Isolation

- Fluid Non-Return (SDNR)

LINE MEDIA:

- Wet/Saturated steam

- Condensate

- High Temperature Hot Water

- Medium Temperature Hot Water

- Low Temperature Hot Water

- Cold ‘Clean’ Water

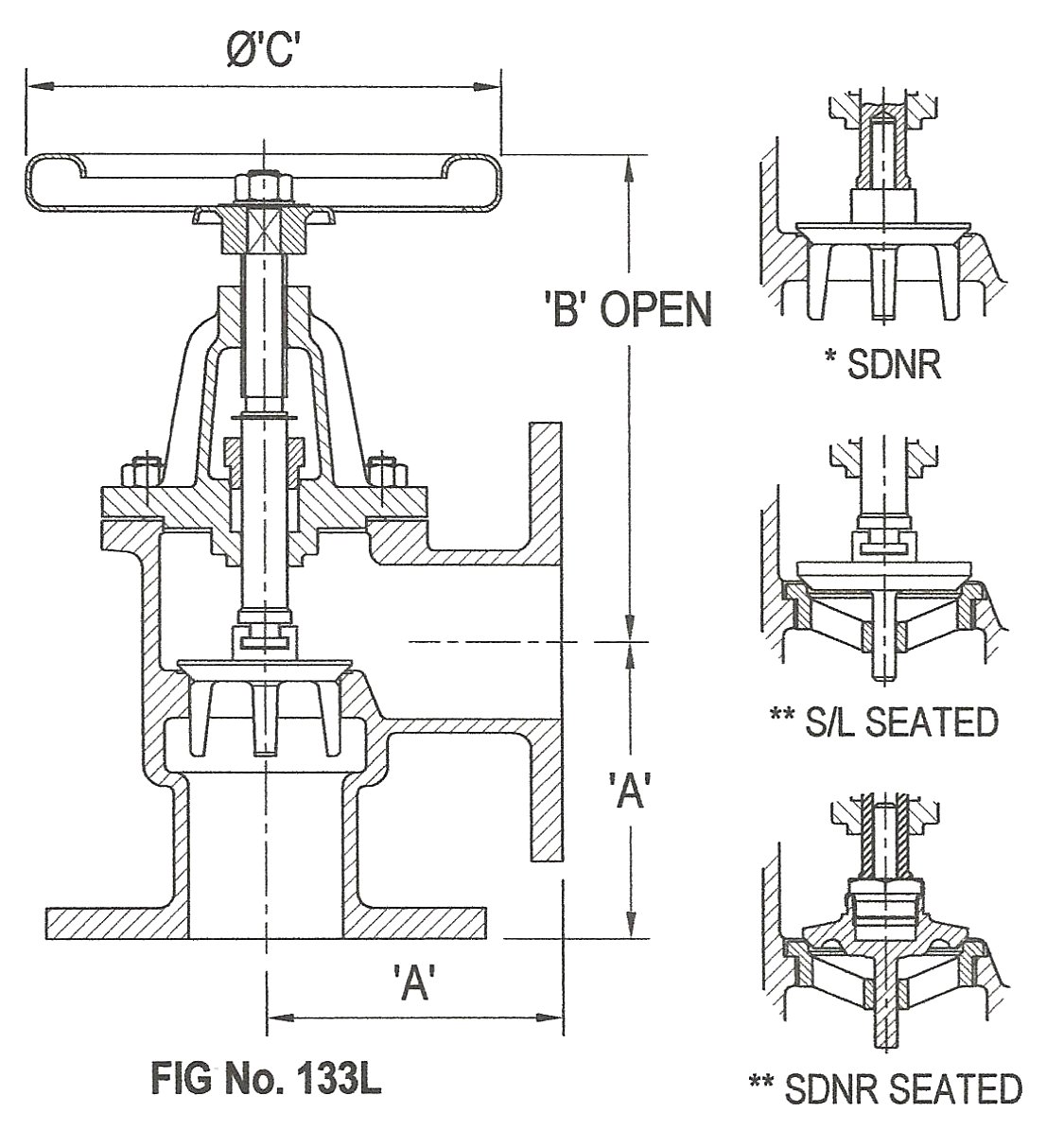

Cast Steel Angle Stop

PRESSURE/ TEMPERATURE RATING:

In accordance with BSI and ANSI Specifications. For the Line Flange Connection required, refer to the Pressure Temperature Rating Chart in the Technical Data Section of our website.

FLANGED:

- BS EN 1092-1 – PN10, PN25, PN16, PN40

- BS 10 Tables – E,F,H,

- ANSI B 16.5 – Class 150

CONSTRUCTION:

MATERIALS:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

OPTIONAL EXTRAS:

- Open and Shut Indicator Locking Device

TYPE OF APPLICATION:

- Isolation

LINE MEDIA:

- Wet/Saturated Steam

- Condensate

- High Temperature Hot Water

- Medium Temperature Hot Water

- Low Temperature Hot Water

- Cold ‘Clean’ Water

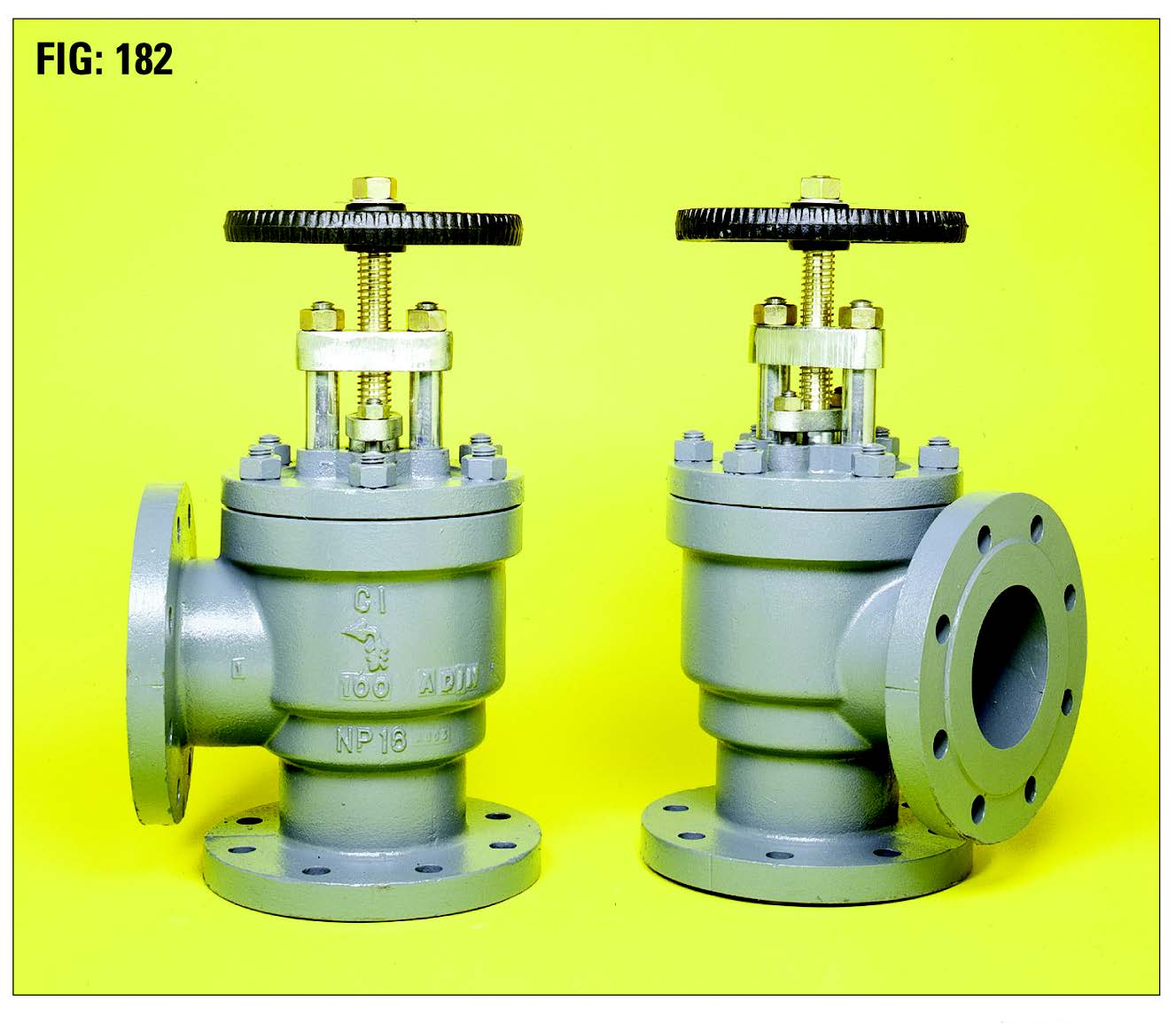

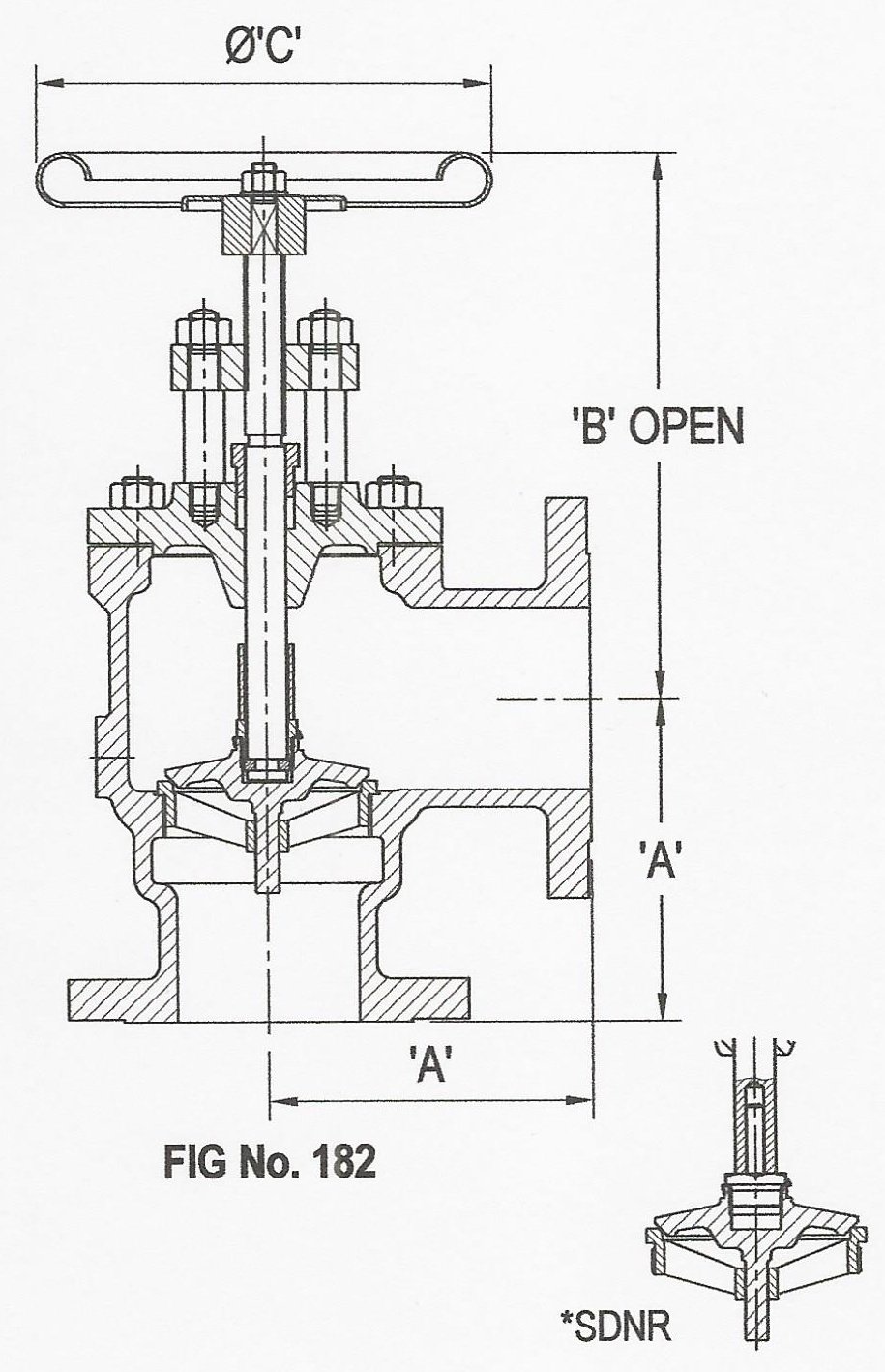

Cast Iron Angle Stop

PRESSURE/ TEMPERATURE RATING:

In accordance with BSI and ANSI Specifications. For the Line Flange Connection required, refer to the Pressure Temperature Rating Chart in the Technical Data Section of our website.

MAXIMUM TEMPERATURE 180°C – RESTRICTED USE

FLANGED:

- BS EN 1092-2 – PN6, PN10, PN16

- BS 10 Tables D, E, F

- ANSI B 16.1 – Class 125

CONSTRUCTION:

MATERIALS:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

OPTIONAL EXTRAS:

- Open and shut indicator Locking device

TYPE OF APPLICATION:

- Isolation

LINE MEDIA:

- High Temperature Hot Water

- Medium Temperature Hot Water

- Low Temperature Hot Water

- Cold “Clean” Water

OPTIONAL EXTRAS:

- Open and Shut Indicator Locking Device

TYPE OF APPLICATION:

- Isolation

- Fluid Non-Return

LINE MEDIA:

- Wet/Saturated Steam

- Condensate

- High Temperature Hot Water

- Medium Temperature Hot Water

- Low Temperature Hot Water

- Cold “Clean” Water