Cast Steel Relief Check for Liquids (external spring)

FLANGED:

- BS EN 1092-1 – PN10, PN16, PN25, PN40

- BS 10 TABLES – E, F, H

- ANSI B 16.5 – Class 150

FOR WATER INDUSTRY USE ONLY WITHIN THE EUROPEAN UNION

CONSTRUCTION:

- This traditional design is suitable for systems with open discharge to atmosphere.

- The external spring is not in contact with the discharge liquid.

- The valve is intended to relieve excess liquid, and must not be used as a safety valve to prevent system failure as referenced in the Pressure Systems Safety Regulations SI 2000 No 128

- Flanges will be drilled unless otherwise specified on order

MATERIALS:

- Body – Carbon Steel to BS EN 10213 gr. GP240GH (WCB) 0.23%C max

- Cover – Carbon Steel BS EN 10028 161 – 430

- Disc – Stainless Steel Casting ASME SA 487 CA6NM class A

- Seat – Stainless Steel Casting to BS EN 10283 1.4408

- Spring – Spring Alloy Steel Design in accordance with BS 1726 Chrome Vanadium Alloy Coated

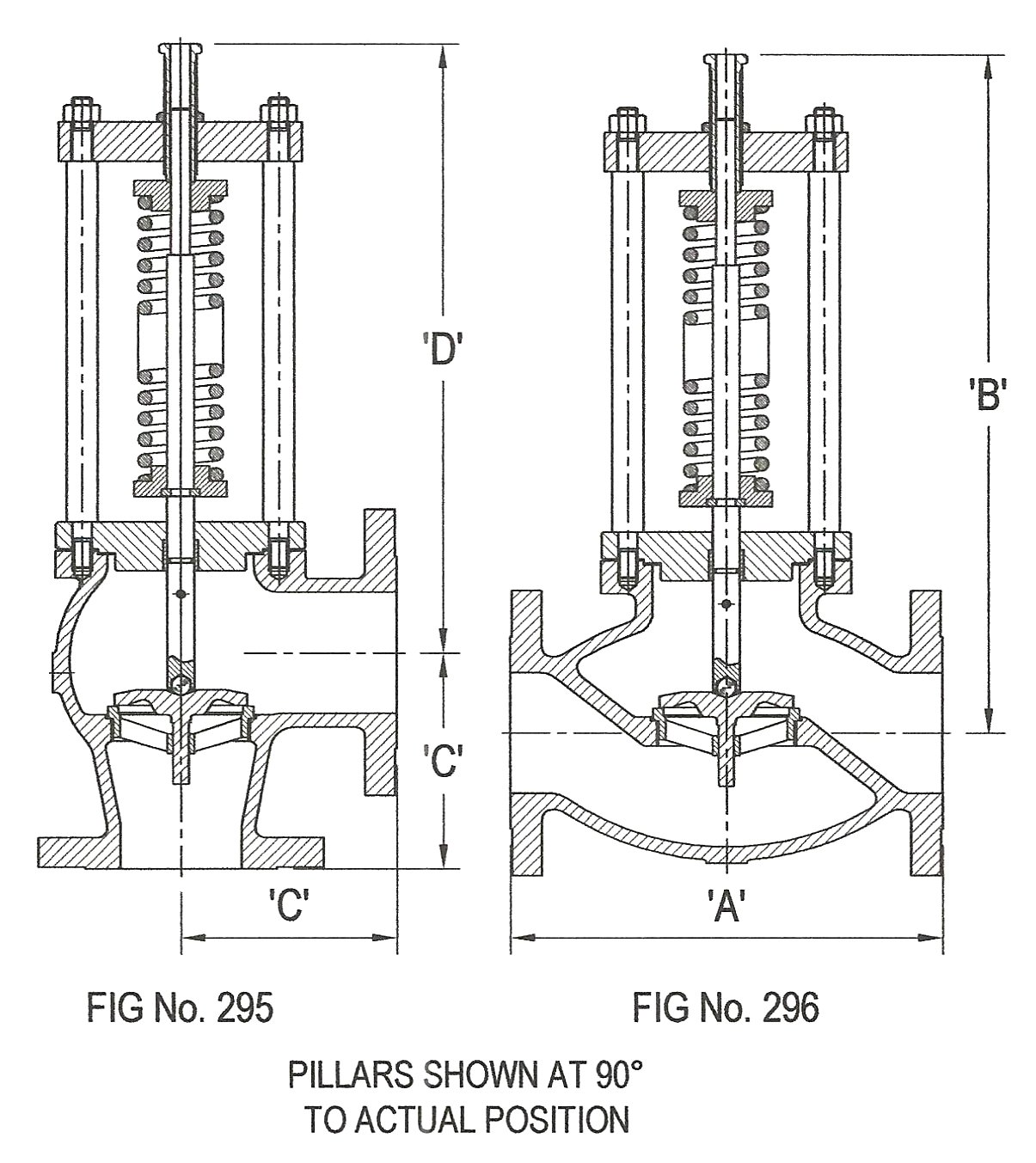

| Nominal Size | Fig. 296 | 50 | 65 | 80 | 100 |

| A | PN10 | 254 | 280 | 305 | 356 |

| A | BST E, F | 254 | 280 | 305 | 356 |

| B | 343 | 400 | 443 | 564 | |

| Nominal Size | Fig. 295 | 50 | 65 | 80 | 100 |

| C | PN10 | 127 | 140 | 152 | 178 |

| C | BST E, F | 127 | 140 | 152 | 178 |

| D | 324 | 360 | 413 | 516 |

PRESSURE / TEMPERATURE RATING:

(Detailed on Valve ID plate)

Minimum set pressure 5psi (0.35 Bar) Maximum set pressure 116psi (8.0 Bar) Maximum Temperature 40°C

STANDARD SPRING RANGE:

Nominal sizes 50mm to 100mm

| Spring No. | PSI | Bar |

| 1 | 5-13 | 0.35 – 0.9 |

| 2 | 10-25 | 0.7 – 1.7 |

| 3 | 20-50 | 1.4 – 3.5 |

| 4 | 40 – 100 | 2.7 – 6.9 |

| 5 | 90 – 116 | 6.2 – 8.0 |

OPTIONAL EXTRAS:

- Easing Lever and Cover

TYPE OF APPLICATION:

- Thermal & Pressure Relief

LINE MEDIA:

- Effluent

- Sewage Sludge