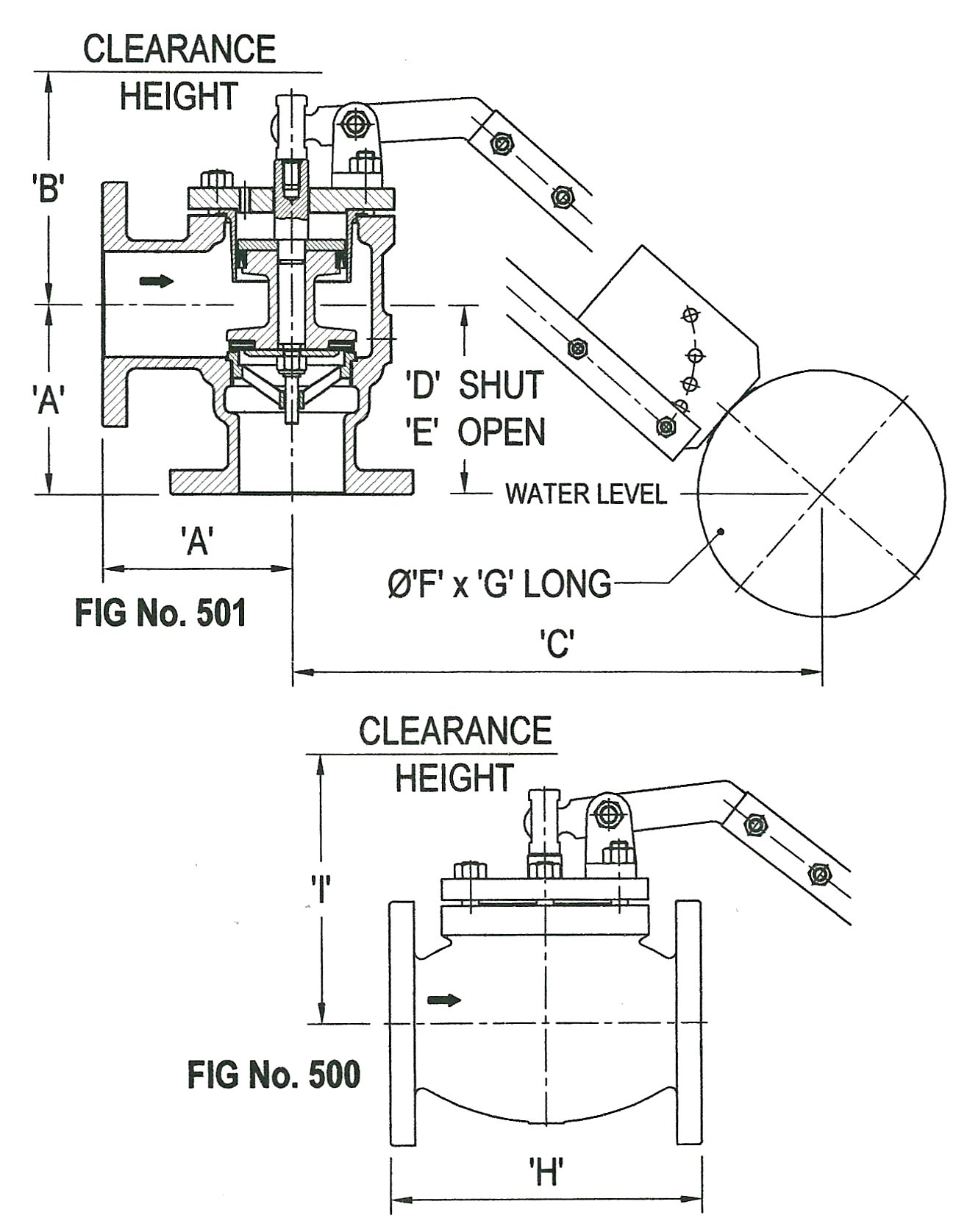

Float Valve | Equilibrium Ball Float Valves

PRESSURE/ TEMPERATURE RATING OF FLOAT VALVE:

50-300mm TEMP. (Max Inlet Water Feed)

10 Bar 23°C

FLANGED: BS 10 Table F

DRILLED:

- BSEN 1092-2 – PN10, PN16

- BS 10 Tables – D, E, F

ANSI B 16.1-Class 125

- Bolted cover plate to protect seal and cylinder of float valve from the ingress of debris.

- Maintenance is simplified by easily replaceable piston and steel reinforced renewable rubber disc.

- Adjustable float for optimum water level control.

- The valves are supplied with the line flanges to BST ‘F’ diameter. Unless otherwise instructed the inlet flange will be drilled to match the flange specified on order. The outlet flange will not be drilled unless ordered.

MATERIALS:

- Body/Cover – Cast Iron to Cover BS EN 1561 EN GJL 250

- Seat Ring/Cylinder- Gunmetal to Valve Seat BS EN 1982 CC491K

- Disc – EPDM Rubber bonded to steel reinforcing plate

- Piston Seal – EPDM Rubber

- Float – Tough Rilsan nylon coating heat-fused to steel

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPROVAL:

- WRAS – Water Regulatory Advisory Scheme

- LPCB – Loss Prevention Certification Board

TYPE OF APPLICATION:

- Reservoir / water storage tank infill

LINE MEDIA:

- Water

- Potable Water